Plastic Recycling Factory Supplying Reprocessing EPE EPS EPP XPS Polystyrene Foam Hot Melting Machine

Description

Basic Info.

| Model NO. | TESJ45~95 |

| Plastic Type | EPS |

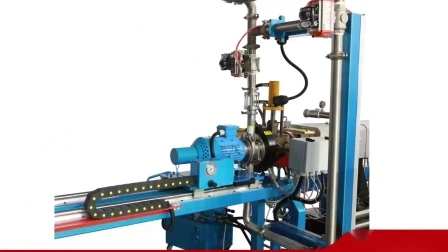

| Screw | Single-Screw |

| Automation | Automation |

| Computerized | Computerized |

| Certification | ISO9001:2008, CE |

| Final Material Status | Block or Bar |

| Electric Grid | 3p 220V~440V 50 or 60Hz |

| After-Sale Service | Eers Available to Service Machinery Overseas |

| Color | Green or Blue Standard Could Be Customized |

| Transport Package | Wrap Film |

| Specification | TFHM100~500 TFCM100~500 |

| Trademark | Retech machinery |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 300~3000kg/H |

Packaging & Delivery

Package Size 16000.00cm * 4000.00cm * 3500.00cm Package Gross Weight 12000.000kgProduct Description

Plastic recycling factory supplying reprocessing EPE EPS EPP XPS polystyrene foam hot melting machineProduct Description

1. As a kind plastic foam densifier, it is applied to a wide usage to compressing and hot melting machine EPS EPP EPE XPS PUR EVA...

2. The hot melting machine could be used in many places, such as super market, schools, hospitals, small-sized warehouse, retail stores, and seafood markets...

3. The hot melting machine has excellent performance, compacting dimension, low noise, easily and convenient operating and maintenance…

4. Ingenious designed feeding hopper, one aspect it could prevent the material jumps out when crushed, the aspect it could also to collect all material into one point to push the material direction down and helping to feed the material into extruder.

5. Exquisite structure of blades, especially experienced designing to the angles of all blades, which could guarantee hot melting machine high efficient crushing performance with high capacity, but also could press the crushed material blocks into the extruder to increase the capacity of whole machine.

With ceramic heaters on the extruder, it could make the material good plasticizing and long life working.

6. The melted material comes out from extruder, it could be collected by steel tank to get material cube block, but also could be cut by automatic pneumatic cutter to get small material blocks. The size of the material blocks could be adjusted.

7. The density of the block can reach 500-600kg per cubic meter. One container can load more than 20 tons material.

| Model | Motor | Capacity |

| TFCM150 | 1.1/3KW | 50kg/h |

| TFCM250 | 4.4/7.5/1.5KW | 100kg/h |

| TFCM350 | 8.8/11/1.5KW | 150kg/h |

1. As a kind plastic foam densifier, it is applied to a wide usage to compress and hot melting machine EPS EPP EPE XPS PUR EVA...

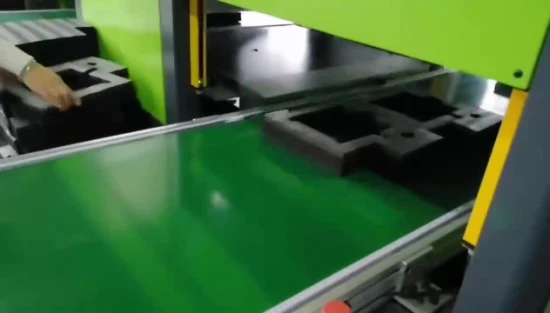

2. The Styrofoam compactor could be used in many places, such as super market, schools, hospitals, small-sized warehouse, retail stores, and seafood markets...3. The Styrofoam compactor press the plastic foam from big to small size high efficiently, the compression ratio could arrive at 1:30~1:50, the compressed material block density could be 350kg/m³, and then it is easy to transport and recycle for next step.

4. The Styrofoam compactor has excellent performance, compacting dimension, low noise, easily and convenient operating and maintenance…

5. Ingenious designed feeding hopper, one aspect it could prevent the material jumps out when crushed, the aspect it could also to collect all material into one point to push the material direction down and helping to feed the material into extruder.

6. Exquisite structure of blades, especially experienced designing to the angles of all blades, which could guarantee high efficient crushing performance with high capacity, but also could press the crushed material blocks into the extruder to increase the capacity of whole machine.

7. Compacting screw and hydraulic pressing, which makes the compression process high efficient and good performance. All parts compacted into one machine, saving cost, low energy consumption, small space covering, which makes the machine to be portable type.8. The Styrofoam compactor is controlled by PLC automatic controlled, easily operating, stable working performance.9. The block is usually compressed to be 250×250mm block.

Our Contact