Reliable and Fully Automatic Granulator Extruder Machine for Recycling Crushed Washed Package Foam

Description

Basic Info.

| Model NO. | FGR500 |

| Plastic Type | PE |

| Screw | Single-Screw |

| Automation | Automation |

| Computerized | Computerized |

| Certification | ISO9001:2008, CE |

| Power | 7.5kw |

| Moto | Siemens |

| Extruder | Sj-45/28 |

| Pipe Diameter | 9~50mm |

| Name | Waste Plastic Recycling Line |

| Raw Material | PVC, PP, PE |

| Electrical Parts | Siemens |

| Inverte | ABB&Others |

| Low Pressure Electrics | Schneider |

| Drying Type | Centrifuge Dryer |

| Inverter | ABB |

| Motor | Siemens Standard Motor |

| Material | Plastic Film, Bags, Basket, Bucket, Pallet |

| Output | 300~2000kg/H |

| Final Product | Granules or Clean Scraps |

| Transport Package | Woodbox with Film Wrapped |

| Specification | FRW |

| Trademark | Faygo |

| Origin | Jiangsu Suzhou |

| HS Code | 84778000 |

| Production Capacity | 100sets Per Month |

Packaging & Delivery

Package Size 420.00cm * 150.00cm * 210.00cm Package Gross Weight 3500.000kgProduct Description

Product Description

Reliable and Fully automatic Granulator Extruder Machine for recycling crushed washed Package Foam

PP PE Film, Pet Bottle crushing, washing and drying line

This line is mainly used to clean the waste plastics, such as PE HDPE LDPE LLDPE PP BOPP Film, bags, PET bottles, Jerry cans, bucket, basket etc. The waste dirty material will go through crushing, washing, drying, and collecting process, and turn to be clean flakes for pelletizing.The production capacity of our crushing and washing line can be 100kg/h to 2000kg/h.

This line mainly include crusher or shredder machine, friction washer machine, float washing tank, High speed friction washer machine, dewatering machine, hot air dryer system, storage silo etc.

The clean material machine from these washing line can be used to making plastic granules. Our company also supply plastic granulating machine for next process

Product Parameters

| Model | FGR300 | FGR500 | FGR800 | Remark |

| Belt conveyer | 1.1kw | 1.1kw | 1.5kw | Washing andSqueeizing part |

| crusher | PC800,37kw | PC1000,45kw | PC1200,55kw | |

| Screw loader | 3kw | 3kw | 4kw | |

| Friction washer | 7.5kw | 7.5kw | 11kw | |

| Float washer | 2.2kw | 3kw | 4kw | |

| Squeeaing Pelletizer | 55kw | 75kw | 110kw | |

| Air cooling system | 4kw | 5.5kw | 7.5kw | |

| Conveyer | 1.1kw | 1.1kw | 1.5kw | Pelletizing Line |

| Single screw extruder | 90kw | 132kw | 160kw | |

| Screen changer and die | 1.5kw | 2.2kw | 3kw | |

| pelletizing system | 1.1kw | 1.5kw | 2.2kw |

PET Bottle Crushing & Washing & Drying line 300kg/h~1500kg/h

PP/PE Film Crushing & Washing & Drying Line 300~1000kg/hPP PE PET Granulating Recycling line 100kg/h~500kg/h

| Extruder model | Motor power | Max capacity | Pelletizing motor | Air blower |

| LSZ51/105 | 22kw | 120kg/h | 1.5kw | 2.2KW |

| LSZ65/1323 | 37kw | 260kg/h | 2.2kw | 3kw |

| LSZ80/156 | 55kw | 400-500kg/h | 3kw | 3KW |

| LSZ92/188 | 90/100kw | 650-800kg/h | 4kw | 4KW |

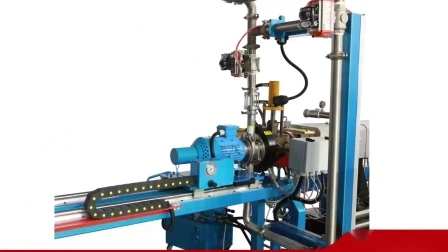

Components of pvc pelletizing machine

a. Conical twin screw extruder:

Using the high efficient conical twin screws, specially designed for PVC power to ensure uniformed plasticization, high extrusion. Stable temperature controlling system can guarantee high quality pipe extrusion.

For CPVC material, the extruder adopt hollow screw, which has oil temperature control system for both screw.

b. Extrusion Mould:

Special mould for PVC and CPVC material, which ensure the pressure of extrusion.

c. Pelletizer:

With hot die face cutter. Pelletizer adopt 4P motor which ensure the pelletizing speed. The pelletizing speed is controlled by inverter

d. air blowing system:

Two stage air blowing system. The granules will be cooled during the air tranportation.

e. vibrator:

To select the good granules.

Please feel free to contact us for more details.

Hot Sales Plastic Machine Recommend:

Automatic Pet Plastic Bottle Moulding Machine & PVC Profile Extrusion Machine & Waste Plastic PP/PE Washing Crusher Recycling

For more details about our waste plastic recycling machine, welcome to send you requests to our company, and we will give you reply in time.

Company Profile

Jiangsu Faygo Union Machinery is a professional manufacturer of plastic machines. It occupied an area of 18000 square meters. With years of development, its products covers plastic extrusion lines, plastic blowing machine, plastic recycling machine, air compressor etc. Stick to the company idea is making good machine, being good person, Faygo Plast alwasy provide customers with high quality machines. Warmly welcome to visit our factory (next to Shanghai)!

FAYGO UNION GROUP has 3 branch factories.

1.FAYGOBLOW which design and make blow molding machine for PET, PE etc. FAYGOBLOW has 5 patents of invention, and 8 patents utility models. FAYGO PET blow molding machine is one of fastest and most energy-efficient design in the world.2.FAYGOPLAST, which make plastic extrusion machinery, including plastic pipe extruding line, plastic profile extruding line. Especially FAYGOPLAST can supply high speed up to 40 m/min PE,PPR pipe line.3.FAYGO RECYCLING, which research new technology in plastic bottle ,film recycling processing and pelletizing. Now FAYGO UNION GROUP has more than 500 customers from different countries.Our factory is located in Zhangjiagang city, covers an area of 26,650 square meters. It only takes around two hours driving from SHANGHAI international airport. Welcome to visit our factory, and hope to cooperate with you in the near future.

FAQ

Q: Your company is a transactional company or an industrial manufacture factory?

A: We are an industrial manufacture factory which locates in Zhangjiagang city.

Q: All of your products are made by your self or compacted via purchasing the others?

A: We have independent technical team who focus on making machines, all the products are made by our technical team.

Q: What is the ability of your factory?

A: About 100 lines per month.

Q: Do you have any other services about your products?

A: We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system.

Q: How do you make the quotation for clients?

A: The price depends on quality and performance but the clients should be satisfied first.

Prev: Plastic Recycling Company Offering Processing EPP EPE EPS EVA XPS Polystyrene Foam Melting Machine

Our Contact