Waste Plastic Polystyrene EPS EPP EPE Cold Pressing Machine

Waste plastic Polystyrene EPS EPP EPE Cold Pressing MachineYurefon EPS plastic foam compactor cold pressing recycling ma

Description

Basic Info.

| Model NO. | YRF-C |

| Type | Cold Pressing |

| Compression Ratio | 50:1 |

| Name | Recycling Machine, EPS Compressor |

| Capacity | 150kg/H-200kg/H |

| Pressing | Hydraulic |

| Control | PLC |

| Crushing | Shaft with Blade |

| Method | Screw |

| Object | EPS Plastic |

| Contactor | Schneider Brand |

| Warranty | 16 Months |

| Inveter | ABB Brand |

| Foam Cold Pressing Compactor Recycling M | Plastic Recycling Machine |

| Motor | Siemens, Wanan |

| Color | Green of Customation |

| Transport Package | Wooden Base, Film Packing |

| Specification | 150kg/h |

| Trademark | YUREFON |

| Origin | China |

| HS Code | 84778000 |

| Production Capacity | 5 Sets Per Months |

Product Description

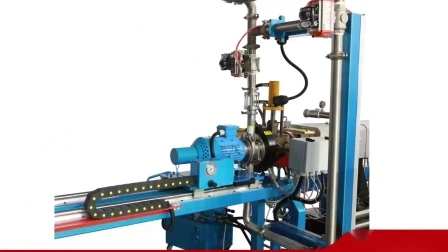

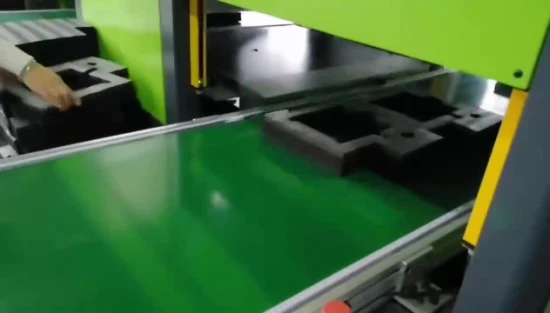

Waste plastic Polystyrene EPS EPP EPE Cold Pressing MachineYurefon EPS plastic foam compactor cold pressing recycling machine is a Styrofoam recycling machine, which can smash the waste Styrofoam materials into small pieces by the blades and gears, and then it could be easily compressed into tight foam ingots at a ratio of 50:1. After compaction, the waste Styrofoam can be reused to make other products, such as frame products and construction moldings.In addition, the applicable materials also include XPS, EPP, food trays and cups. Yurefon EPS recycling machine is able to eliminate all your waste foam recycling concerns.

EPS recycling machine to reduce the size of expanded polystyrene foam and expanded polypropylene foam for easier transportation. It is also called EPS densifier and EPS compactor. It is widely used in sea food processing plant, electronic factories, White goods and black goods stores, and the supermarkets.

Description of Waste plastic Polystyrene EPS EPP EPE Cold Pressing Machine:

1.Twin shaft crushing blades. This machine adopts manual feeding, the material will be crushed by blades on the twin shaft, then through the screen conveyed into the barrel of the main machine.

2.The screw of the main machine can compression, then extruding them and hydraulic blade cut them to pieces for easy storage and transportation.

3.The shapes of the products can be designed according to customers' requirements.

Working principle:

The twin shaft are two parallel shafts with blades, they running in different rotation direction. Each shaft has blades and driven by the gear box, to crushing the EPS material then the material will get throught the sreen into the barrel. The material will be processed by the high speed rotary screw to the barrel, then the high press to reduce the volume density.

For the environment:

1.EPS is uniquely recyclable - all manufacturing waste can be fully reprocessed as can the products at end-of-life.

2.EPS is comprised of 98% air and therefore only 2% polystyrene making it a highly efficient use of raw material.

3.Although EPS is derived from a non-renewable resouce - oil, it represents less than 0.1% of crude oil usage.

4.As EPS is highly energy efficient - the energy saved over the lifetime of an insulation panel.

Parameters of Waste plastic Polystyrene EPS EPP EPE Cold Pressing Machine

| model | YRF-C-200 |

| Yield | 150kg/h |

| Screw diameter | Φ350mm |

| Feed port size | 1000mmx600mm |

| Screw speed | 36rpm |

| Crusher blade | Four axes 10+11+10+11 |

| Crusher speed | 120rpm |

| Main motor | 11kw |

| Crusher motor | 2.2kw X 4 |

| Hydraulic pump motor | 1.5kw |

| Product Size | 380x380mm |

| Machine dimensions | 4800x1500x2500 |

| Weight | 1800kg |

We are professional Packaging Foam Plastic Board EPS EPE EPP EVA Cold Pressing Machine manufacturers.

If you want to know more detailed information, please feel free to contact me:

Mob: +86-13372135960 (Whtap/ Vber/ Telgrm/ Line)

Our Contact

Send now